|

|

|

|

|

|

|

|

|

|

|

|

|

|

Direct Gear Design

Service Mark Registration

|

|

|

Direct Gear Design

|

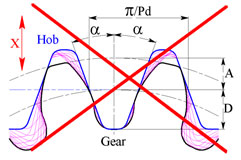

Gear geometry - primary,

tooling parameters - secondary

Gear geometry - primary,

tooling parameters - secondary

|

Traditional gear design utilizing rack generation and preselected (primarily standard) tooling parameters

provides universally satisfactory performance for standard gear applications. However, Direct Gear

DesignŽ is an application-driven gear drive development process that mainly emphasizes performance

maximization and cost efficiency without concern for predefined tooling parameters. It optimizes the

gear tooth flank and fillet profiles and works perfectly with any gear application that demands high

technical and market performance.

Modern Direct Gear Design's foundation is the Theory of

Generalized Parameters created by Prof. E.B. Vulgakov. Please visit the Publications page for more

details about the Direct Gear Design method.

|

|

|

Asymmetric Gears

|

|

The two profiles (sides) of a gear tooth are functionally different for most gear drives. The workload on

one tooth profile is significantly higher and is applied for a longer operating time than for the opposite

tooth profile. The asymmetric tooth shape reflects this functional difference to improve the

performance of the drive tooth profiles on account of the performance of the opposite coast tooth

profiles. The coast tooth profiles are typically unloaded or lightly loaded during a relatively short work

period. Direct Gear Design of the asymmetric gears independently defines the drive tooth profile for

maximum load capacity, the cost tooth profile, and the fillet for sufficient gear tooth flexibility. It

provides high gear transmission performance with low noise and vibration.

|

|

|

Tooth Flank and Root Profile Optimization

|

|

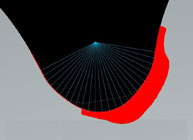

Optimization of the involute gear tooth flank allows for maximum gear mesh efficiency and tooth

surface endurance. The proprietary fillet profile optimization technique evenly distributes the bending

stress along the fillet profile, reducing stress concentration. It significantly reduces the root bending

stress level by comparison with the best currently used tooth root fillet profiles. This bending stress

reduction is also exchangeable for an additional increase in tooth wear resistance, efficiency, and

lifetime of a gear transmission.

|

|

|

High Gear Ratio Planetary Drives

|

|

AKGears has developed and implemented high gear ratio planetary arrangements. These arrangements

enable gear ratios from 20:1 to over 200:1 in one gear stage and from 200:1 up to 100,000:1 in two gear

stages. These planetary systems contain a minimum number of components, provide higher load

capacity, and have less tolerance sensitivity than harmonic or orbiting drives.

|

|

|

Enveloping Crossed Helical Gears

|

|

Crossed helical gears have been known for centuries; however, unlike parallel helical gears, their applications are limited to low load-carrying capacity gear drives. A reason is their point contact in the meshing zone, which results in high Hertzian contact stresses that diminish the tooth flank endurance. The application of the enveloping tooth shape allows for a significant contact stress reduction and a severalfold increase in load-carrying capacity compared to conventional crossed helical gears, which makes it possible to consider their application in moderate to highly loaded gear transmissions.

|

|

|

Self-Locking Gears

|

|

Most gear drives are back-drivable or inertia-drivable. For many gear drives, the back or inertia

drivability is not acceptable. Such gear drives utilize different brake systems. Some self-locking, non-

back-drivable gear drives (with worm gears, for example) do not require brakes. However, such drives

typically have a high gear ratio, low efficiency, and angled or crossed axes. Based on previous studies,

AKGears has developed and implemented the parallel-axis self-locking gears. These gears can utilize any

gear ratio from 1:1 and higher. They prevent either inertia driving, back driving, or both and can be

external, internal, or incorporated into the planetary gear stage. Their gear mesh efficiency is

significantly higher than in existing self-locking gear drives.

|

|

|

Plastic Gears

|

|

Direct Gear DesignŽ works ideally for plastic gears,

providing total design flexibility that is not achievable

using traditional gear design. It compensates for

plastics' low strength and low thermal conductivity by

balancing pinion and gear tooth bending stresses,

reducing the bending stress concentration, and

minimizing and balancing specific sliding velocities,

resulting in maximum efficiency and minimum heat

generation.

|

|

|

|